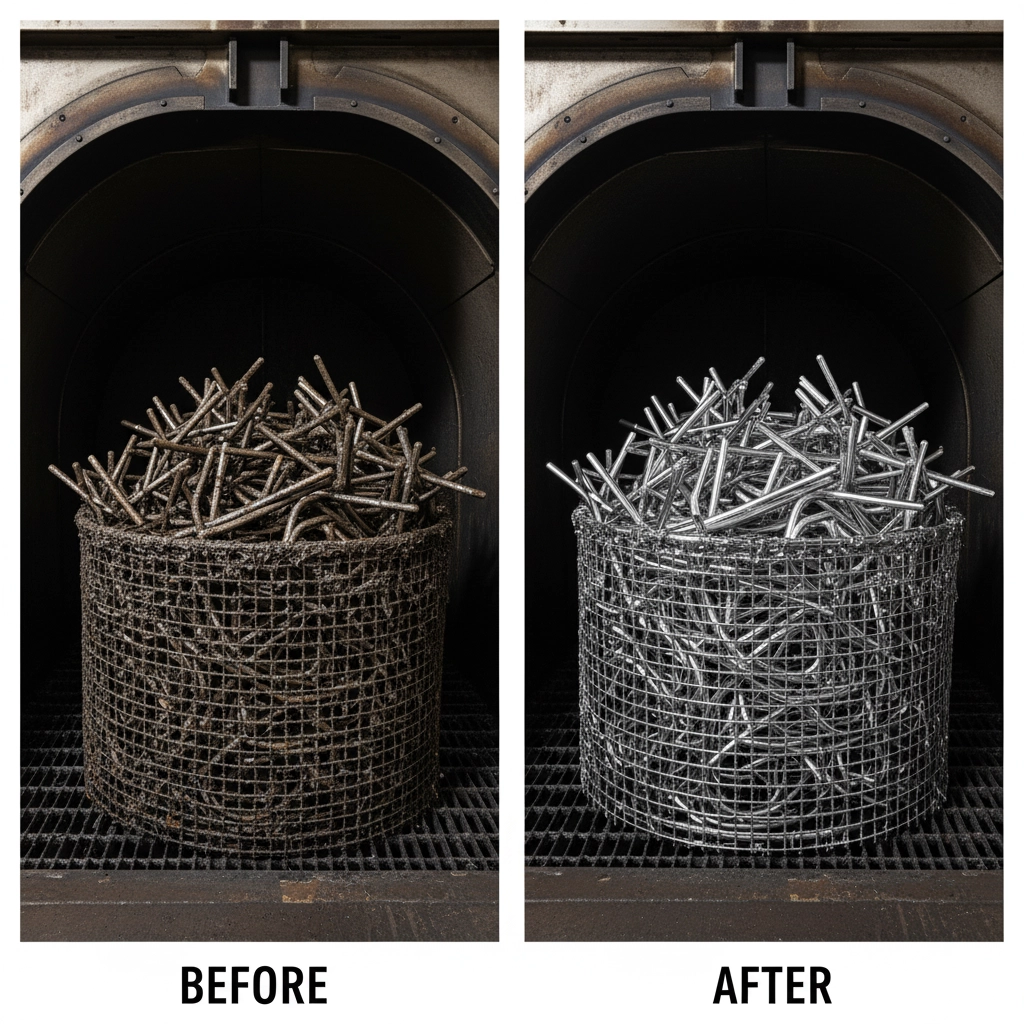

Hanger Cleaning Oven, Environmentally Friendly and Effective Paint Removal Solution;

Developed by MT Makina, the ATF-50 Hanger Cleaning Oven is a high-temperature, environmentally friendly curing system used in industrial cleaning processes. This system, particularly popular in automotive, metalworking, furniture, and paint facilities, was developed to effectively remove coatings accumulated on hangers, hooks, busbars, grills, engine housings, conveyor chains, and incorrectly painted metal parts used in industrial painting lines.

The furnace's basic operating principle is to break down the organic and inorganic chemical bonds in paint, grease, polymers, residual oil, and cataphoresis coatings using high temperatures in a flameless, low-oxygen atmosphere. This completely removes surface residue, leaves the part surface unharmed, and eliminates the use of any chemicals. This minimizes environmental waste and makes the cleaning process safe, sustainable, and economical.

Working Principle:

First, the Primary Burner heats the pyrolysis chamber to 420°C to thermally decompose organic materials or polymers in a low-oxygen atmosphere. These materials are released as smoke and directed to the secondary combustion chamber (afterburner) where they are burned directly by the flame. As a result of this process, only odorless and harmless H₂O (steam) and CO₂ are released into the atmosphere through the chimney outlet.

Throughout the process, a heat-sensor probe located in the oxidation chamber continuously monitors the smoke rate emitted by the parts by measuring the flue temperature. When the flue temperature reaches a predetermined value, the control system activates a water spray system to cool the parts. This process reduces the smoke release rate, preventing the risk of ignition. Furthermore, the water spray system is automatically activated when the furnace temperature exceeds the setpoint by 30°C.

The ATF-50 model, with its energy-efficient structure, low operating costs, powerful heating capacity, and compact design, is an ideal solution for production facilities of all sizes. Its environmentally friendly operating principle ensures low emissions, offering a significant advantage for companies aiming for sustainable production.

Advantages of the Hanger Cleaning Oven

.webp)

Developed by MT Makina, the ATF-50 Hanger Cleaning Oven is an environmentally friendly, fully automatic solution that increases efficiency in industrial cleaning applications. This oven system effectively removes paint, grease, polymer, oil, dust, and cataphoresis coatings from materials such as hangers, hooks, busbars, grills, motor housings, and incorrectly painted metal parts without the use of chemicals. The ATF-50 model operates in a flameless, low-oxygen environment, providing high-temperature cleaning. This method breaks down coatings and completely removes them from the surface. Because it does not use chemicals, environmental waste is minimized. Furthermore, this system, with its low emissions, does not harm the environment and contributes to an environmentally friendly production approach.

Thanks to its fully automatic operating principle, the furnace starts with a single button and completes the cleaning cycle in 2 to 4 hours. This process requires no operator intervention, saving time while reducing labor costs. The system, which can operate with natural gas, LPG, or diesel fuel, can be easily integrated into any business's infrastructure. The ATF-50 Suspended Cleaning Furnace is also equipped with safety features. The automatic explosion vent located in the ceiling prevents potential risks by providing emergency opening in case of internal pressure increases. Furthermore, the railed loading cart allows for easy handling and placement of heavy parts, reducing operator physical workload and increasing production efficiency.

Thanks to its robust construction made of high-quality materials, the oven offers long-lasting and durable use. It can be custom-built to meet various needs, from compact models to large-capacity industrial systems. Its low maintenance requirements minimize operating costs. The PLC-controlled touch panel that manages the entire system allows easy monitoring of temperature, time, and safety parameters. This allows operators to maintain full process control and operate with high safety and efficiency. The ATF-50 Hanger Cleaning Oven is a superior industrial cleaning solution that combines performance, safety, environmental responsibility, and cost savings.

Hanger Cleaning Oven Performance and Efficiency

Yüksek Kapasitede Alevsiz Temizlik

430–500°C’de alevsiz ortamda kaplamaları güvenle temizler, yüzeyi korur.

Çift Yanma Odası

Kaplamaları parçalar, gazları yakarak düşük emisyon ve yüksek verimlilik sağlar.

Otomatik Kontrol

PLC sistemiyle tek tuşla çalışır, 2–4 saatte temizlik döngüsünü tamamlar.

Enerji ve Güvenlik

İzolasyonlu gövde enerji tasarrufu sağlar, otomatik kapanma sistemi güvenliği artırır.

Clean Energy, Clean Air: Healthy Environment with Flue Gas Purification!

Hanger Cleaning Furnace Chimney Washing Systems

MT Makina's Hanger Cleaning Ovens are environmentally friendly systems that clean paint, grease, polymer, and cataphoresis coatings at high temperatures without the use of chemicals. Flue cleaning systems play a critical role in ensuring that the gases and particles released during this process are safely released into the atmosphere.

Chimney cleaning systems are essential for both environmental compliance and operational safety. Different methods are used depending on the technology used:

Wet Chimney Washing System

Gases are filtered through a water-based filtration system to capture harmful compounds. This method is particularly effective for gases with high humidity and dense particulates.

Dry Chimney Washing System

Gases are filtered through special filters and absorbent materials to remove harmful components. It stands out with its low maintenance requirements and economical operating costs.

Semi-Dry Chimney Washing System

This system, a combination of wet and dry filtration methods, provides both high efficiency and low water consumption. Its flexible operating conditions make it easily adaptable to different production facilities.

Gas Filtration and Emission Monitoring

Gas filtration systems used at the chimney outlet minimize emissions. Integrated emission monitoring systems ensure full compliance with environmental standards through continuous measurement.

Why Chimney Washing System?

-

Environmentally Friendly Solution: Prevents environmental damage by reducing emissions.

-

Legal Compliance: Ensures compliance with international environmental regulations.

-

Employee Safety: Prevents harmful gases from leaking into the work environment.

-

Long-lasting Use: Increases the durability of furnace and chimney systems.

Hanger Cleaning Oven Application Areas:

YF-1000C Garbage Waste Incinerator: Wide Range of Applications and Disposable Waste Types

Offering effective solutions to waste management needs in various sectors, the YF-1000C Garbage Waste Incinerator stands out with its safe destruction capability at high temperatures. It offers a wide range of uses from industrial production to the health sector, from municipal services to commercial facilities. It provides maximum security without harming the environment, especially in the disposal of infected or hazardous waste.

Safe Usage Areas in Different Sectors

With its versatile structure, the YF-1000C Garbage Waste Incinerator can be used safely in the following areas:

-

Healthcare Institutions: Infectious waste generated in hospitals, medical centers and laboratories is destroyed under hygienic conditions.

-

Industrial and Commercial Enterprises: Organic and inorganic wastes from production facilities are disposed of safely without harming the environment.

-

Municipal Waste Management: Domestic waste and other solid waste generated in urban areas are effectively destroyed.

-

Crisis and Epidemic Periods: High-risk wastes occurring during epidemics are disposed of quickly and safely.

Types of Waste That Can Be Disposed of

With its feature of providing complete combustion at high temperatures, the YF-1000C Waste Incinerator destroys the following types of waste without harming the environment:

-

Domestic and Industrial Waste: Organic, plastic and metal wastes are burned with high efficiency and rendered harmless.

-

Infectious and Contagious Waste: Medical waste is destroyed without carrying pathogens and microbial risks.

-

Food Waste: Organic waste originating from the food industry is disposed of without creating odor or risk.

-

Chemical and Biological Waste: Hazardous waste from laboratories and industrial establishments are disposed of safely.

-

Textile Production Waste: Fabric, fiber and production residues are destroyed by burning without harming the environment.

Environmentally Friendly, High Performance Waste Disposal

The YF-1000C Waste Incinerator is equipped with the latest technology flue gas purification systems. While it does not leave any harmful residues after the incineration process, emissions are effectively controlled thanks to integrated filtering systems. In this way, air quality is preserved and an environmentally friendly waste management process is provided.

Garbage Waste Incinerator

Automatic Loading System

.webp)

YF-1000C Garbage Waste Incinerator: Safe and Highly Efficient Waste Disposal with Automatic Loading System

Drawing attention with its high technology and environmentally friendly features, the YF-1000C Garbage Waste Incinerator offers safety and efficiency together in waste disposal processes. The advanced automatic loading system ensures that waste is transferred to the furnace in a regular, fast and controlled manner. This system increases operational efficiency while also maximizing employee safety.

A New Era in Productivity with Automatic Loading

YF-1000C Garbage Waste Incinerator is powered by automatic loading technology to provide continuous and balanced waste feeding. This system allows waste to be transferred directly, without contact and in a controlled manner to the furnace. As a result, the combustion process continues more stably, safely and efficiently.

Key Benefits of Automatic Loading System

-

Uninterrupted and Controlled Feeding: Waste is transferred to the furnace continuously and equally, thus maintaining high combustion quality and ensuring energy efficiency.

-

Employee Safety and Hygiene: Direct contact with hazardous or infectious waste is prevented, helping to protect staff.

-

Low Labor, High Efficiency: The need for manual handling is eliminated, thus reducing labor usage and increasing process speed.

-

Energy Saving and Stable Combustion: Balanced loading keeps the furnace temperature constant, which optimizes energy consumption.

-

Environmental Protection: The effective feeding system increases combustion efficiency and reduces emission rates to a minimum level, providing an environmentally friendly solution.

Integrated Disposal Process with Advanced Technology

The YF-1000C Garbage Waste Incinerator increases both environmental safety and operational performance when equipped with an automatic loading system. Developed in accordance with the sustainable waste management approach, this system is an ideal choice for industrial and municipal applications.

Garbage Waste Incinerator

Automatic Ash Discharge System

.webp)

YF-1000C Garbage Waste Incinerator: Uninterrupted and Safe Operation with Automatic Ash Discharge System

Developed to provide high-performance waste disposal, the YF-1000C Garbage Waste Incinerator increases process efficiency and safety with its automatic ash discharge system. After the combustion process is completed, the ash formed is discharged safely and regularly without the need for operator intervention. This advanced system supports operational continuity and eliminates the need for manual intervention.

Ash Discharge Technology That Increases Efficiency

YF-1000C Garbage Waste Incinerator enables automatic removal of ash accumulation, allowing the combustion process to continue uninterrupted. It reduces the need for systematic cleaning, maintains performance stability in long-term use and significantly shortens maintenance times.

Key Advantages of Automatic Ash Discharge System

-

Guaranteed Continuous Operation: Automatic ash evacuation ensures that the combustion process continues without interruption.

-

Safe and Contactless Operation: Creates safe working conditions by preventing operators from coming into direct contact with high-temperature residues.

-

Effective Use of Time and Labor: There is no need for manual labor for ash cleaning, which allows human resources to be used in more efficient areas.

-

Clean and Efficient Combustion Area: The system maintains the cleanliness of the furnace by preventing ash accumulation in the combustion chamber, providing an efficient combustion process.

-

Long-Lasting Performance: By preventing ash accumulation and system blockages, the long-lasting and healthy operation of the furnace is ensured.

Modern and Sustainable Waste Disposal Solution

YF-1000C Garbage Waste Incinerator not only saves labor and time thanks to its automatic ash discharge system, but also offers an environmentally friendly working process. A powerful solution for industrial and municipal purposes, this furnace perfectly combines sustainability and operational efficiency in waste disposal.

YF-1000C GARBAGE WASTE INCINERATOR TECHNICAL SPECIFICATIONS

Waste: Garbage

Model: YF-1000C

Capacity: 1000 Kg/H

Feed Cover Opening: Hydraulic Piston

Cover Lock: Hydraulic Piston

Waste Feed: Automatic

Ash Discharge: Automatic

Second Combustion Chamber: Available

Combustion Fan: Available

Chimney Washing: Wet Washing Unit

Flue Gas Exhaust Fan: Available

Working Temperature: 850-1200 C

Refractory Concrete Resistance: 1600 C

Inside the Oven: Fire Concrete

Insulation: Ceramic Fiber

Safety: Safety Switches and Emergency Stop Buttons

Water Level Meter: Available

Electrical Panel: PLC Automation and Inverter Drive

Observation Window: Heat Resistant Glass

Chimney: 310 Stainless Steel

Burner Brand: Ecoflam

Fuel Type: Diesel / Natural Gas / LPG

Fuel Alternative: Single or Dual Fuel

Fuel Tank: Available

Gas Holding Time: 2 Sec.

Container Lifting System: Optional

Fire Brick: Optional

Dry Filtration: Optional

Heat Recovery: Optional

Continuous Emission Monitoring: Optional

.webp)